The beginning of every project is picking the right hardware for the job. In our case we need to check off a few boxes seeing how we are dealing with a car environment.

Temperature Resistance

How will the hardware react to extreme cold and hot temperatures? You would be surprised how many issues can come up with cheaply sourced chips or other electronic components. Your best bet is to pick components designed for an automotive environments. Yes, it will be more expensive but you will avoid many headaches.

Vibration Resistance

How will your hardware react to extended exposure to vibration? Again, picking automotive components is the easy way out but not always a choice. When in doubt, a test is always a good idea.

EMI Resistance

A car environment is very noisy in terms of electromagnetic interference. Get your hardware in the car and test it out. Does it still work when you try to roll the windows down or blast the radio? Good. What happens to the Bluetooth module you are planning to use when you place it close to other components in the car? Does it still work?

Life Span

Your project might work well those few times you used it but will it truly work well for years to come? Double check the datasheets for your components and make sure they will last for years under normal use.

Getting Some Power

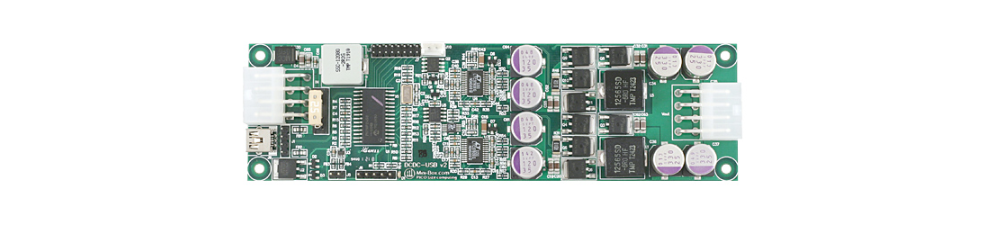

Sure, you can connect your project straight to the battery but should you really be doing that? Always use a fuse and a clean power supply. One supply that we can recommend is the DCDC-USB-200 from Mini-Box.

Apart from outputting clean power, it can also be programmed to do exactly what you need it to do. You want it to keep your hardware on for 15 seconds after you shut off the car? It can do that. How about send a power on/off signal to your project or car pc? It can do that as well.

The more time you spend picking and testing the right components, the less time you will be spending replacing components down the road.